PROCESS

- Reduction of steering column ends and tube die-cutting

- End forming of 5 different tube models

TECHNOLOGIES

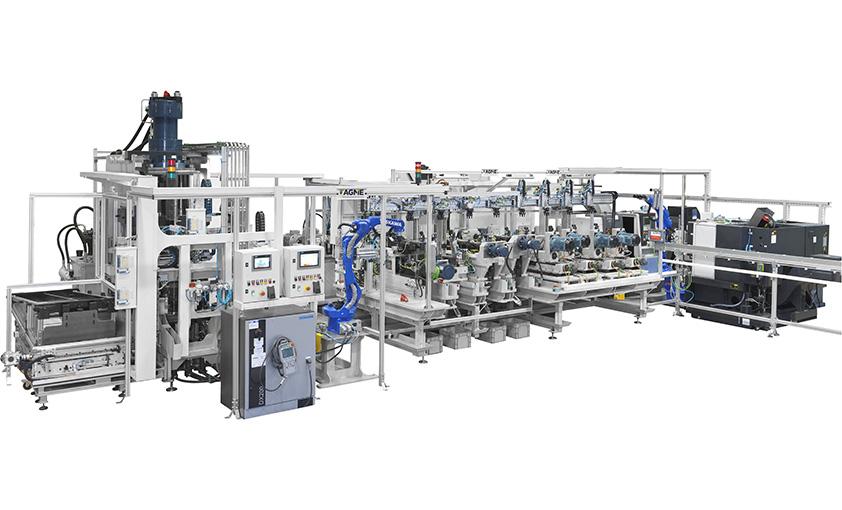

- Automatic feeding and handling of components

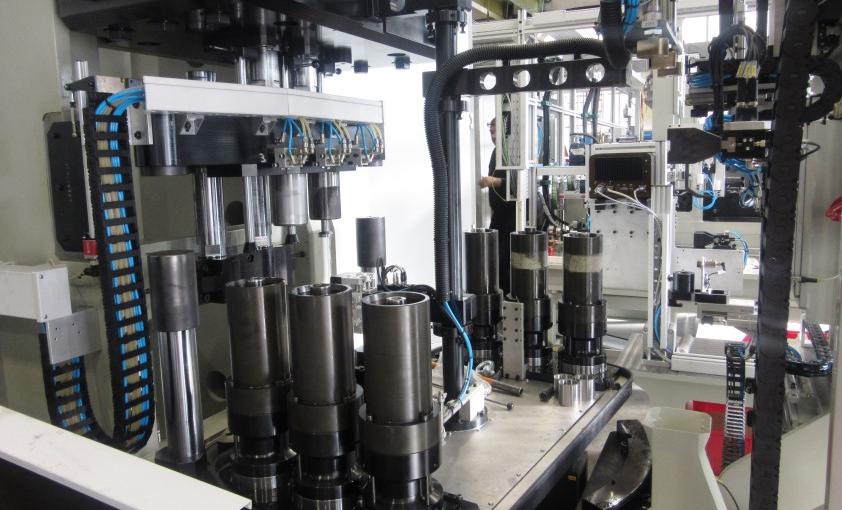

- Tube deformation

- Design and manufacture of special tooling and fixtures

- Tube height and diameter control

- Robotized loading and unloading of tubes

- Transfer process

- Die-cutting and drilling

- Threading

- Programming

- Process automation

- Remote service

ADVANTAGES

- Integration of two machines connected by a robot into a single solution where forming, machining, punching and threading processes are carried out without the need to generate intermediate stocks.

- Flexible customized machine, valid for five tube models by changing only the special tools.

- Improved process accuracy and production continuity

- Optimisation of production times

- Guaranteed quality and homogeneity of the tubes

- Robust and compact automatic machine that saves space in the plant

- EC declaration of conformity