AGME announces the launching of its new electric servo presses: PE-15 and PE-100 models, developed to meet the growing demand for high-precision, energy-efficient and fully traceable pressing operations. Both models are now ready for delivery, offering a new level of performance, control and reliability.

These two models expand AGME’s electric press portfolio, complementing the already well-established and industry-proven PE-50, a benchmark solution widely adopted in automated assembly lines. With the addition of the PE-15 and PE-100, customers can now choose from a more comprehensive force range to suit both fine-precision applications and demanding high-load processes.

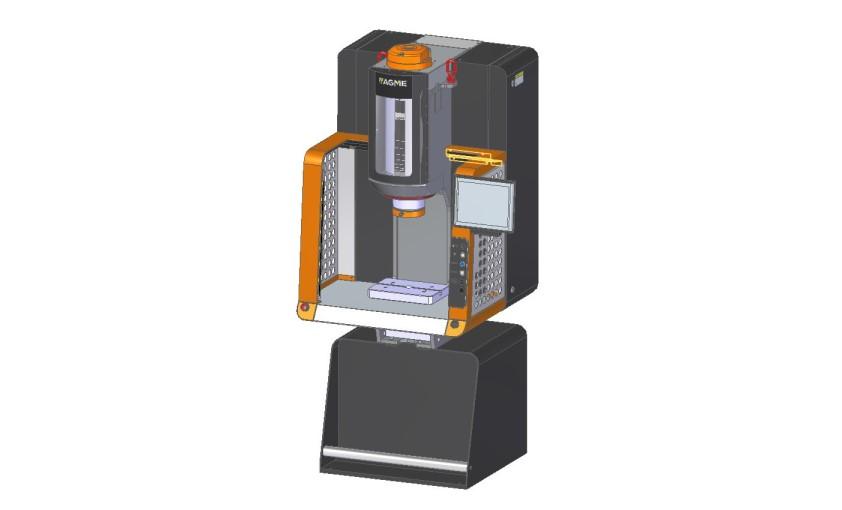

- AGME PE-15 electric press with 1.5 tonnes of force. It is ideal for small and medium pressing operations where precision, repeatability and low energy consumption are critical.

- AGME PE-100 electric press with 10 tonnes of force for more demanding works, ensuring stable pressing performance and full process control.

Both models feature a compact and modular design, available as CE-certified standalone machines or as pressing heads for perfect integration into automated assembly systems or special-purpose machinery.

Engineered with intelligent control, open PLC architecture and advanced monitoring capabilities, the expanded PE Series provides complete visibility of:

- the pressing curve (force-displacement)

- process monitoring by windows, envelope, and measurement and monitoring of contact position, final position, final force and distance.

All process data can be recorded, exported and analysed, enabling full traceability, enhanced quality assurance and compliance with the most demanding industrial standards. Their energy-efficient electric actuation and low-maintenance design substantially reduce operating costs compared to conventional hydraulic solutions.

With these new launches, AGME strengthens its leadership in precision pressing and automated assembly technologies, supporting automotive component manufacturers, integrators and industrial OEMs in optimising their production processes.

👉 For technical specifications, integration advice or a quotation, please contact us